What is the Purpose of Swaging Cable?

When dealing with cables, especially those for electrical power or other demanding applications, it is essential to learn how to make secure connections. One such method that is trusted immensely is swaging. Swaging is a procedure that alters the shape of a metal sleeve or fitting surrounding a cable to make it a solid fitting. But what is the purpose of swaging cable, and how does a cable swaging tool help the process? Therefore, this article will describe the use, advantages, and uses of cable swaging to understand why it is crucial for high-performance cables and systems.

What Is Swaging?

Swaging is a unique method of metal forming; in this method, pressure is applied to a metal sleeve, commonly known as a ferrule, to give it a desired shape that conforms to the shape of a cable. Swaging produces a distribution of pressure from a round shape to the desired form, creating uniform contact with the material. A swaging tool is used in the process; therefore, a cable swaging tool is essential. This instrument is designed to apply force to the sleeve or ferrule and secure it firmly in place against the cable. It has made it easy to develop a solid and stable bond that can handle pressure and tension to a reasonable level. An ideal example is the IWS-1608M cable swaging tool.

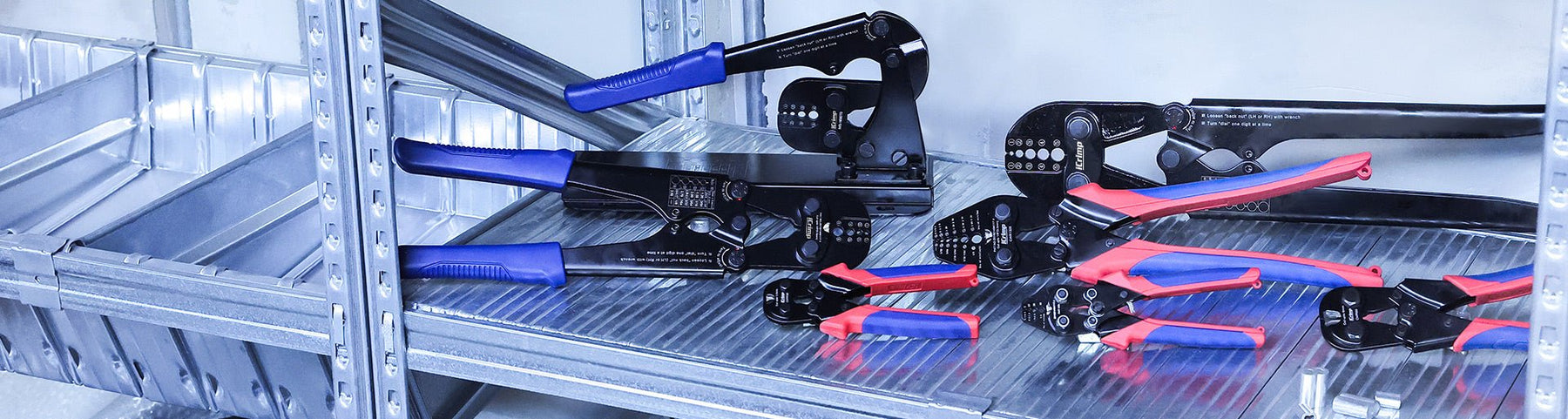

Types of Swaging Tools

Various swaging tools are available, each designed for a specific purpose. Common types include:

Hydraulic Swaging Tools

This tool utilizes hydraulic pressure to squeeze the metal, thereby providing a solid and practical swaging process.

Pneumatic Swaging Tools

Pneumatic swaging tools utilize compressed air as their power source and can be integrated into production lines. A good example is the Pneumatic Swaging Tool.

Manual Swaging Tools

Manual tools are employed where the usage is not continuous or restricted to small-scale projects. The Swaging Tool for 1/32"-1/8" Aluminum Oval Sleeves Wire Rope Cables is an ideal example.

Read more: What Are the Two Types of Swaging Tools?

The Purpose of Swaging Cable

The swaging cable's primary function is to provide a secure and solid cable termination to its corresponding fitting. Here are some of the main reasons why swaging is used:

-

Strength and Durability

Swaging gives more strength than other connections. Swaged fittings enable any cable to safely withstand heavy loads without slippage or degradation when used with a cable swaging tool. That is why swaging is applied successfully in fields where safety is crucial, such as bridge building, designing aircraft, and marine rigging.

-

Corrosion Resistance

In many applications, particularly when cables are used in marine or outdoor environments, they are at high risk of corrosion. Swaged fittings, available in various types and made from corrosion–resistant materials such as stainless steel, enhance protection compared to typical fittings that may wear out over time, thus compromising the connection.

-

Aesthetic and Streamlined Finish

Swaged connections give a neat work finish. It, however, results in a more aesthetically pleasing end product because swaging is not invasive and does not produce deformities like the application of other methods, which may make buildings look odd, or the addition of bulky and conspicuous swages.

-

Longevity

Swaged connections are intended to be permanent. Therefore, when used, the fitting will not be able to be unscrewed or loosened, minimizing the need for periodic checks on the building and reducing construction and follow-up costs.

-

Waterproofing

It is also worth mentioning that when this connection is made, it can be made watertight, preventing water from entering the cable and causing damage.

Applications of Swaging

Swaging is widely used in various industries, including:

-

Telecommunications

Arrange cables as links between the networking equipment and the networking facilities.

-

Electrical Systems

It is used for proper cable fixings, especially for terminals and connectors.

-

Automotive

It is used to connect cables with the electrical parts of automobiles.

-

Industrial Applications

Flexible cables transport power to machines and equipment.

Benefits of Swaging

Swaging offers several advantages over other methods of cable termination:

-

Reliability

The swaged connections are considered vital since their area of contact measures a large area of the stranded wire.

-

Efficiency

Swaging is fast; thus, it can save time and be the cheapest in terms of human resource use.

-

Versatility

This method can be applied to any cable connection fitting.

Bottom Line

Generally, swaging has numerous applications and uses across various fields, serving as an effective solution for securing and terminating cables. Knowing these, you can decide on the optimal application of swaging and choose the correct tools. Swaging is one of the most effective methods for establishing cable connections, whether dealing with telecommunication networks, electrical wiring, or industrial equipment. The best tools from iCrimp for swaged connections ensure safe and long-lasting connections for a long time.

References